- Joined

- Jun 10, 2019

- Messages

- 1,776

- Media

- 503

- Reaction score

- 1,588

- Location

- Corona Del Mar, California

- Grill

- Timberline 850

RemE....

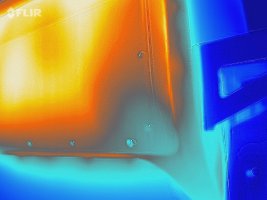

I worked on it this AM, I ran a 450 temp burn in last night, and had a 100 degree gradient. Changed the exhaust from the box to the shield and ran it again, this time started at 165 as it looks like I am going to need a gradient map now that the Traeger is insulated. Pre-insulation 400 to 200 took 7 min ,insulated it takes 64.

With all probes showing an internal grill temp of 165-178 the infrared thermometer shows 83 -87 depending on where you take the temp.TheTraeger set to 165 the FB right side shows 173 , the left side shows 183. I don’t konw how I will be able to use “keep warm” if I can not set it to a temp below175....

Looks great, from that rear install I would put a big triangle in each corner to take that heat blast. Don't forget to insulate between the stainless and the sheetmetal back cover (even if it's the thin stuff) when replacing it as well.

Regarding keep warm. If you are around you could open the grill and dump some heat. Yes, the insulation holds the temp inside very well. On my last brisket, I was away when it was to hit 203 so I just shut the grill down and it coasted gracefully down in temp. Got home, transferred the meat to my cooler and rested it till we ate, 3 hours later. The meat was still very hot to the touch!

Maybe in colder outside temps, keep warm might be needed, the option is there, and +10F is not too far off really.

I am LOVING this brisket, my best one yet! I gave some to a neighbor, he and his wife said that they love brisket, have eaten it all over Texas, and that this was one of the best they've ever had. God Bless Matt Pittman, and his weekday brisket recipe!