Look forward to the rest but was there a reason why you had the insulation and your aluminum square inside the Bella?

The insulation and stainless square help make the seal and protect the RTV from direct heat. The squares also protect the delicate insulation.

With the top and bottom sealed, the Bella does not leak any brown gunk and stays nice and clean outside.

The air supply to the sealed lid prevents smoke and steam from rising and wetting the unburned pellet supply.

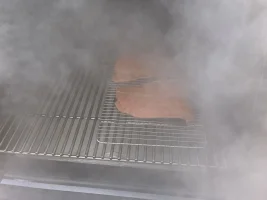

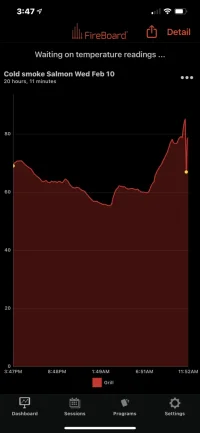

From my 20 hour cold smoke Salmon test yesterday the Turbo Bella worked like magic!

1- Used 50/50 alder pellets and Western maple chips.

2- Because the bottom is now sealed, the burning takes place mostly around the injector. I put in about 1.5 inches of fine sawdust first, this soaks up burn residue and doesn't burn.

3- Lit both sides for 30 seconds with torch.

4- All 4 ports fully open (top, sides, and injector) and ran the pump at about 60% speed.

Smoke was always visible wafting out of the grill exhaust. The barrel was packed with smoke. I checked pellet level and was amazed at how little fuel was needed, it dropped maybe 2 inches in 8-9 hours!

Also, if you keep the Bella somewhat full, the top cover remains only warm to the touch as the fire stays in the middle of the unit.

When done smoking, I turned off the pump, closed all 4 valves. The Bella just snuffed out and was cool in an hour. I removed the bottom and let the pellets and ash drop into a aluminum pan, I added some water, then threw out the mush. There was zero residue on the bottom cover, because of the sawdust in the bottom!

Personally, I pulled the smoke tube, injector tube, and side elbows and cleaned them. Then scraped the insides of the Bella. It looks good as new.

Next, the Grill, big lesson learned. Cold smoking overnight causes lots of condensation inside the grill! Smoked condensate is amber brown, is messy, and is everywhere! What a mess.

Next time I will remove the drip pan, baffle, and put a towel in the bottom. I had to wear gloves and wipe everything down, pull and wash everything else.

So, the Turbo Bella mod is excellent, however my two day cold smoked salmon was a complete failure! I need to go back to the drawing board on the curing process as it was so salty, inedible. I was crushed, but the look and texture was perfect.

Also, the recipe stated that the grill temps should not exceed 80F. It was supposed to be cold the next day but full sun came out and I had trouble shading the grill. When the grill temp hit 80 I pulled plug at 20 hours.